No more missing

tools.

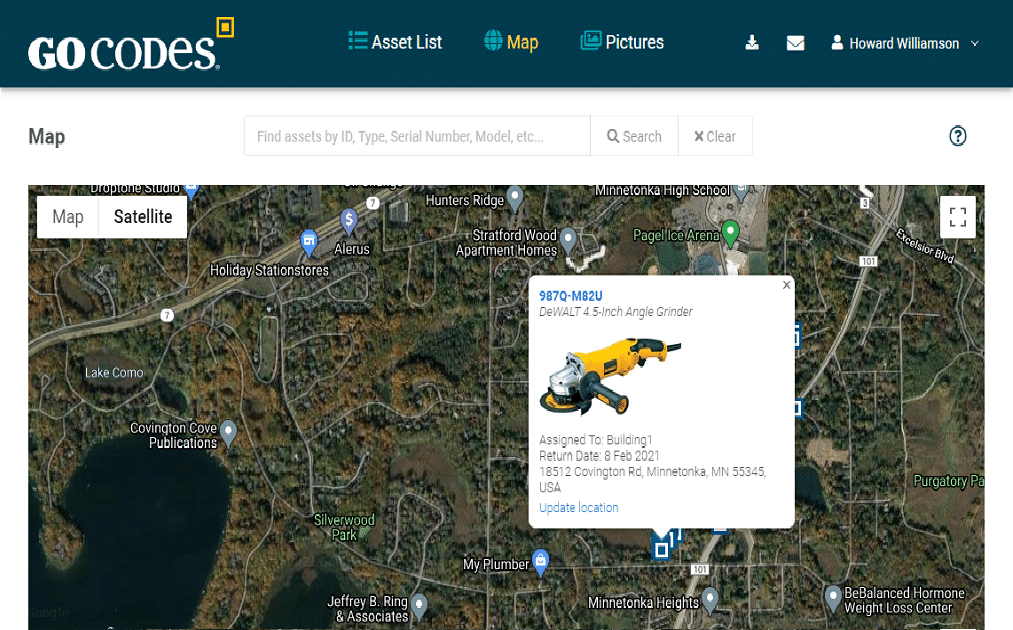

Take control with GoCodes! Know what your tools are, where they are & who has them at all times, using our one-stop, tool tracking solution.

We make tool tracking easy!

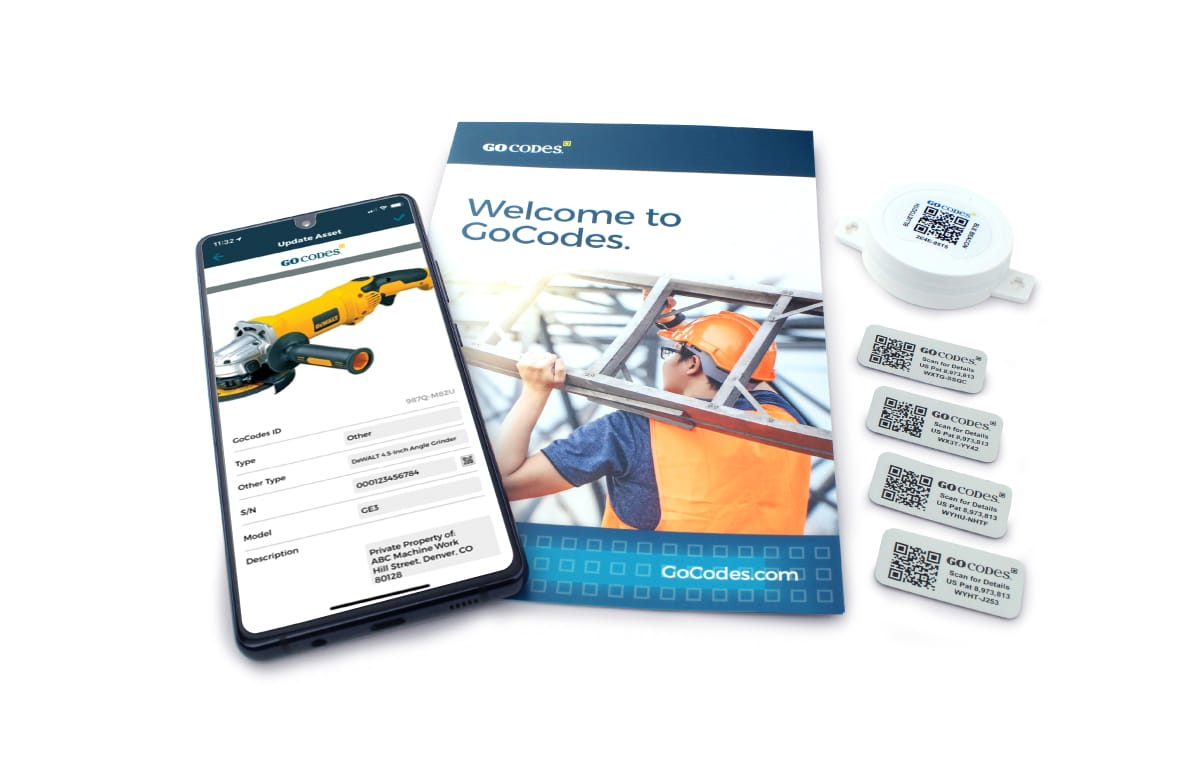

Use our app-store 4.7 star-rated mobile app to check your equipment in and out, from anywhere. Get going in minutes, with your customized QR code rugged, metal tags. Build reports in seconds to show tool utilization & more.

- Patented QR Codes

- Rugged Metal Tags

- Work Order Mgmt.

- Document Mgmt.

- Material Mgmt.

- Bluetooth Beacons

- Custom Reporting

- Equipment Utilization

- Fixed Asset Accounting

- Automated Audits

- Fast Checkout

- Automatic GPS Tracking

- Work Offline

- Kitting

- Training Included

Rugged Tags

Rugged, custom tags come in a range of materials and specifications. Tag everything from heavy machinery to hand tools. Metal tags are sold at wholesale prices – a 20% discount.

Built for Trades

Save time using our lightning-fast scanner apps that work on any device & enable you to check out tools in seconds, on-the-go, from any location.